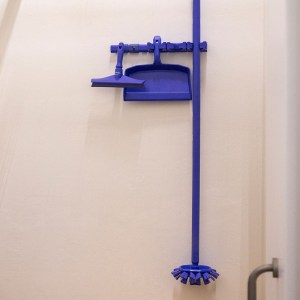

Vikan 7030 UST Tank Brush – 190 mm – Hard

The Vikan 7030 UST Tank Brush – 190 mm – Hard features Ultra Safe Technology (UST) for maximum bristle security and hygiene. Its angled bristles and seamless design ensure optimal cleaning performance while minimizing contamination risks. Glass & Fork certified and FDA-compliant, this brush is perfect for cleaning tanks, vats, silos, and food-contact surfaces.

The Vikan 7030 UST Tank Brush – 190 mm – Hard is designed using Ultra Safe Technology (UST) to provide unparalleled bristle security and hygiene. Its seamless and easy-to-clean design eliminates areas where contaminants can accumulate, making it ideal for food and beverage production facilities such as dairies, breweries, and wineries.

The angled bristle pattern ensures thorough cleaning of tanks, vats, silos, and large food-contact surfaces, while the wide drainage holes prevent water pooling and allow for quick drying during storage. This compact and lightweight brush is also ideal for cleaning complex equipment like mixers and blenders.

The Vikan UST Tank Brush is Glass & Fork certified, FDA-compliant, and meets EU and UK food contact regulations, ensuring safe use in hygiene-sensitive environments. With a maximum heat resistance of 121°C (autoclave sterilization) and chemical resistance from pH 2 to pH 10.5, this brush is built for durability and efficiency in professional cleaning applications.

Key Features:

- Ultra Safe Technology (UST) for maximum bristle retention and hygiene.

- Angled bristles ensure deep cleaning in tanks, vats, and silos.

- Seamless, easy-to-clean design reduces contamination risks.

- Glass & Fork certified and FDA-compliant for food-contact applications.

- Wide drainage holes prevent water pooling and aid drying.

- Heat-resistant up to 121°C for autoclave sterilization.

- Compatible with Vikan threaded handles for versatile use.

Benefits:

- Minimizes bristle loss, reducing foreign body contamination risks.

- Ensures a hygienic cleaning process with its seamless construction.

- Improves efficiency with an ergonomic and lightweight design.

- Withstands high temperatures and chemicals, ensuring long lifespan.

- Supports color-coded cleaning systems to prevent cross-contamination.

Ideal Use Cases:

- Food & beverage production (dairies, breweries, wineries, etc.).

- Tank and silo cleaning in industrial and hygiene-critical environments.

- Mixers, blenders, and large equipment in food processing facilities.

- Pharmaceutical and healthcare industries requiring high hygiene standards.

- HACCP-certified environments, supporting color-coded cleaning systems.

Frequently Asked Questions (FAQ)

- What is Vikan UST? Vikan UST (Ultra Safe Technology) is a line of hygienic cleaning brushes specifically designed for food processing environments.

- Why should I use Vikan UST brushes? They significantly reduce contamination risks, improve cleaning efficiency, and are ergonomically designed for user comfort.

- Are Vikan UST brushes suitable for all cleaning tasks? They are ideal for high-risk environments but may not be necessary for general cleaning purposes.

- How does color-coding help in hygiene management? Color-coding prevents cross-contamination by clearly distinguishing brushes for different tasks or areas.

- How durable are Vikan UST products? Vikan UST products are highly durable, reducing the frequency of replacements.

- Are these brushes easy to maintain? Yes, their hygienic design allows for easier cleaning and quicker drying.

- Do Vikan UST products comply with food safety standards? Yes, they are designed to meet stringent food safety and hygiene regulations.

- Where can I purchase Vikan UST brushes? Vikan UST products can be purchased directly from Vikan’s authorized distributors and selected retailers.

Fictional Case Study: Implementation of Vikan UST at FreshSafe Foods

Company Background:

FreshSafe Foods serves the food processing industry in the Netherlands, supplying quality products to hospitality and catering businesses nationwide. Committed to safety and quality, the company prioritizes adherence to the highest hygiene standards.

Problem Statement:

During an internal audit, FreshSafe Foods identified significant hygiene concerns involving their cleaning tools. Traditional brushes were difficult to clean, leading to bacterial accumulation, increasing cross-contamination risks. Additionally, brush fibers detached frequently, risking product contamination and endangering food safety.

Why Choose Vikan UST?

Vikan’s Ultra Safe Technology (UST) brushes offer superior hygienic features, such as easy-to-clean surfaces, quick-drying capabilities, and ergonomic designs. These tools significantly reduce the risk of product contamination due to their hygienic design, ergonomic advantages, and durable construction. Vikan UST products comply with stringent food safety standards and simplify cleaning routines.

When UST May Not Be Necessary:

In non-critical environments, such as general cleaning tasks outside food processing, the advanced hygienic features of UST brushes may not be essential. In such scenarios, standard cleaning tools can suffice.

Solution Implementation:

FreshSafe Foods took the following steps to adopt Vikan’s UST:

- Risk Assessment: Identified high-risk contamination areas.

- Staff Training: Provided comprehensive training on correct use and maintenance of UST tools.

- Color-Coding: Introduced color-coded UST products to prevent cross-contamination.

- Maintenance Protocols: Established clear guidelines for the routine inspection and cleaning of tools.

Results:

Following the implementation of Vikan UST products, FreshSafe Foods observed significant improvements:

- Enhanced Food Safety: Hygienic design reduced contamination risks significantly.

- Improved Cleaning Efficiency: Ergonomic and hygienic designs enabled quicker, more thorough cleaning.

- Cost Reduction: Durable materials decreased tool replacement frequency, resulting in operational cost savings.

Conclusion:

Investing in Vikan UST products has notably improved food safety, cleaning efficiency, and cost-effectiveness at FreshSafe Foods. This case highlights the importance of selecting appropriate, high-quality cleaning tools in food processing environments.

Check out our brochure for more information.

Click here to download the brochureDeclaration of Compliance

Contact Us

AAVA

Office

Oosteinde 22

1674 NB Opperdoes

Netherlands

+31 227 725 901

info@aava.nl

Stay Connected

Follow us. Never miss an update.

Secured Payment

We accept Paypal Ideal and credit cards.

- Visa

- Mastercard

- Diners Club

- Amex

- PayPal

English (UK)

English (UK)  Nederlands (NL)

Nederlands (NL)  Français (FR)

Français (FR)  Español (ES)

Español (ES)  Italiano (IT)

Italiano (IT)  Deutsch (DE)

Deutsch (DE)